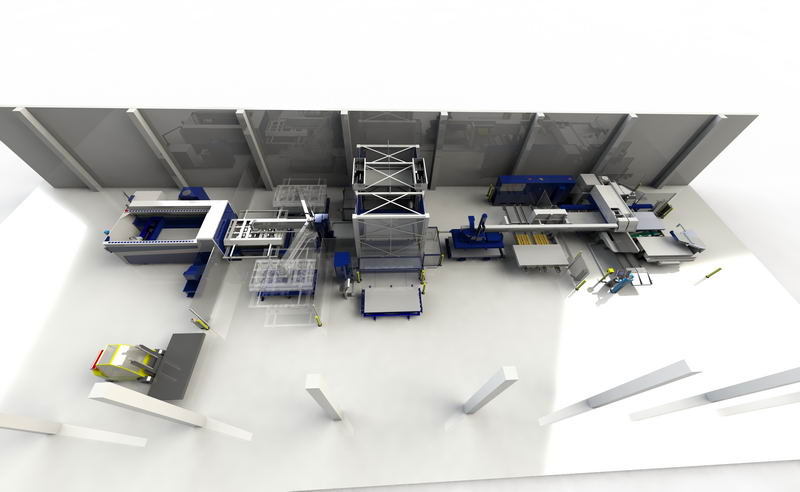

- Trumpf flatbed laser with max. 8 kW cutting power and a max. processing size of 4000x2000x25 mm

- Fibre and CO2

- Separation between machines for steel and stainless steel / aluminium / brass / copper

- Cutting accuracy +/- 0.1 mm

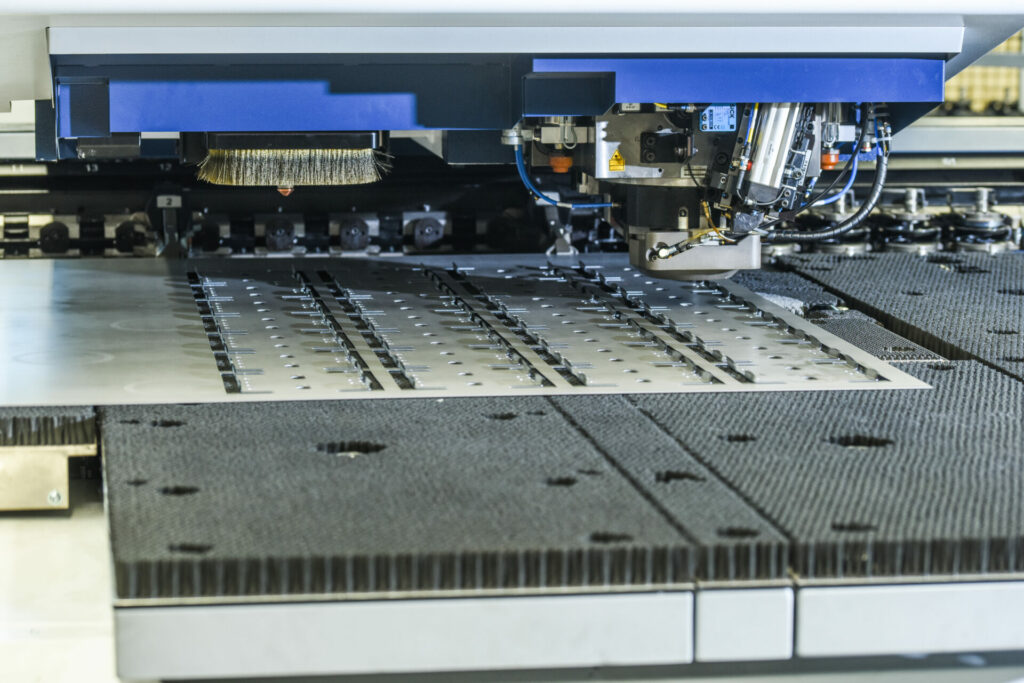

Lasering - Punching

- Processing of thin sheet metal (up to 6 mm) with the highest surface requirements and complexity on our fully automated system including threads, forming, etc.

- the advantages of laser cutting and punching (holes, openings, threads, forming, embossing and much more) are combined in just one clamping operation – with high quality and maximum precision

- Active mould; free of machining marks and deformations upwards and downwards